3D printing

The Technology

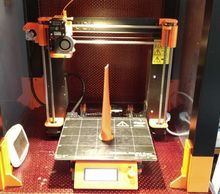

The Original Pruse I3

The Technology

Additive manufacture is the overall name for processes which build items by progressive addition of materials in layers. The technology allows the manufacture of near net shape or fully finished parts in metals and polymers. It can also be used as an intermediate step in manufacturing ceramics.

The machine

The Original Pruse I3

The Technology

The RepRap project, started in 2005, was to make a machine capable of manufacturing itself. The result was a number of designs which allowed 3d printing of plastics on cheap and easily made machines. These use the Fused Deposition Modeling process (FDM) in which polymer filament is melted and deposited by a moving extruder.

The Original Pruse I3

The Original Pruse I3

The Original Pruse I3

Probably the most popular printer is the Prusa I3. This is an open source design and although many types exist, those made by Josef Prusa have an obvious advantage. I own one of these but have also used Stratsys and Ultimaker printers.

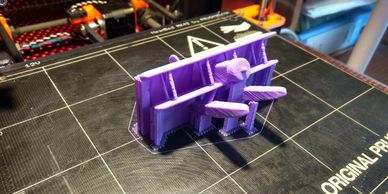

Biomechanical parts

Biomechanical parts

The Original Pruse I3

The ability to create parts for analysis means that detailed test can be performed on replica parts to aid surgery, treatment, or for research.

Applications

Biomechanical parts

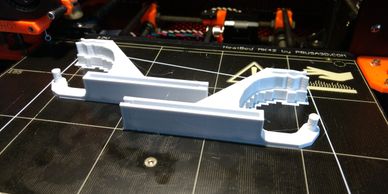

The Thingiverse

Small volume components for research, repair or bespoke application. Novel structures and materials. Apart from finished parts these relatively simple and cheap printers can make intermediate state parts which are then completed to make metals, ceramics and composites.

The Thingiverse

Biomechanical parts

The Thingiverse

Thingiverse.com is the main repository of 3D designs. Search it for things to build or just for ideas. Start at my page which has some of the things i have printed and a couple of things i designed.

Copyright © 2018 Ian Horsfall - All Rights Reserved.

Powered by GoDaddy